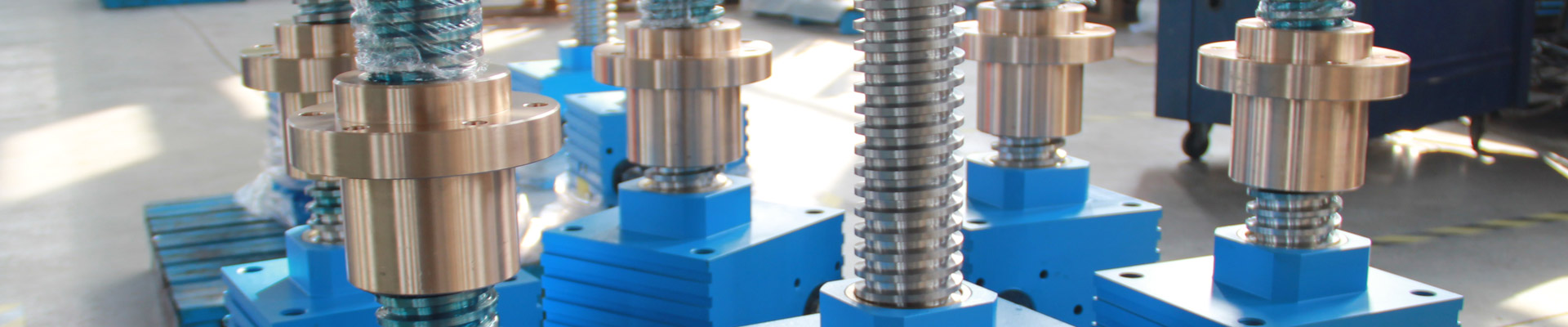

Worm Gear Ball Screw Jacks Specifications

Worm Gear Ball Screw Jacks Ordering Information Part Number:

SJD100 - US - T - C - 1/8 - 300 - P

1 2 3 4 5 6 7

1: Jack Model

SJD10, SJD11, SJD12, SJD20, SJD21, SJD22, SJD50, SJD51, SJD80, SJD81, SJD100, SJD101

Before selecting the jack model, please check above worm gear ball screw jacks specifications.

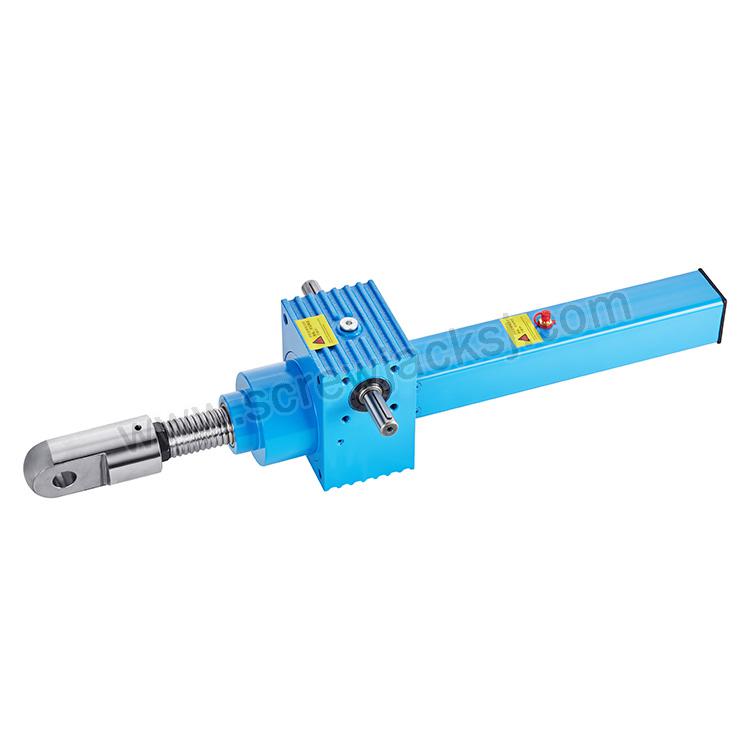

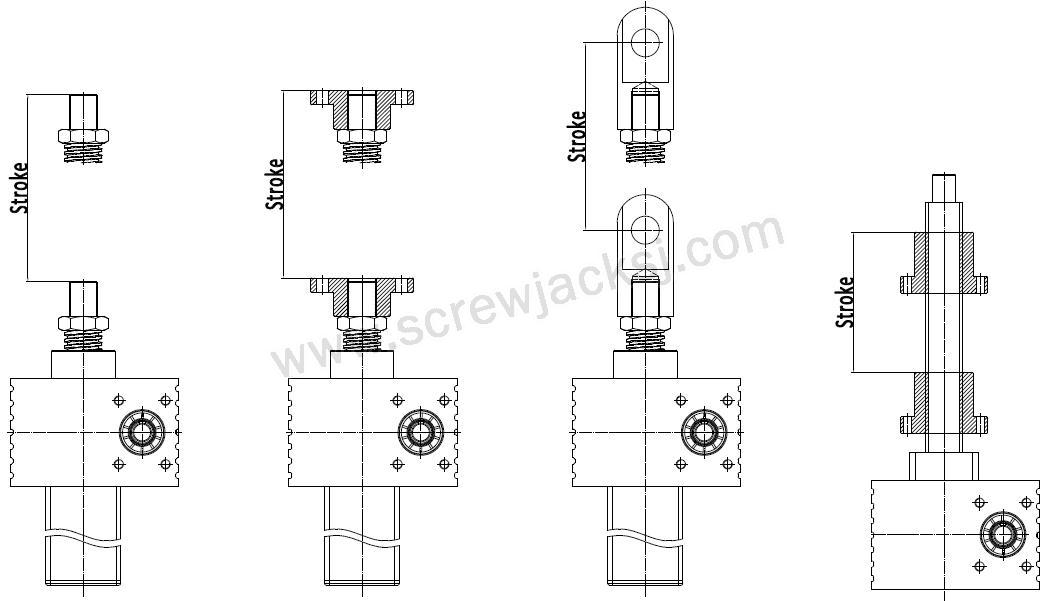

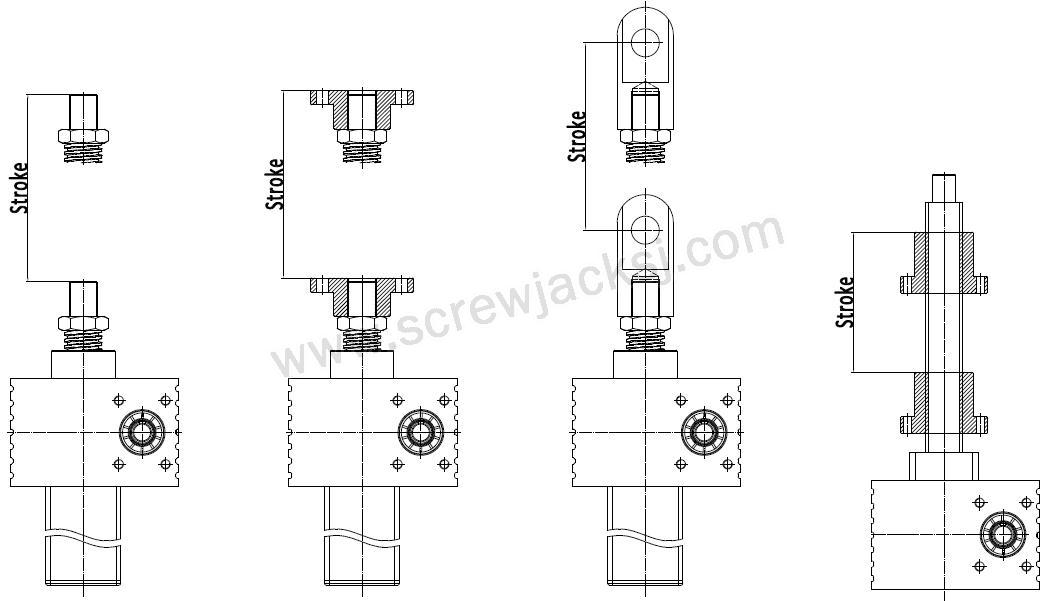

2: Screw Configuration & Mounting Orientation

US: Upright translating screw UK: Upright keyed screw UR: Upright rotating screw

IS: Inverted translating screw IK: Inverted keyed screw IR: Inverted rotating screw

Note:US,IS (Screw rotation, do axial motion) UK, IK (Screw anti-rotation, do axial motion) UR,IR(Screw fixed rotation, traveling nut do axial motion)

US IS UK IK UR IR

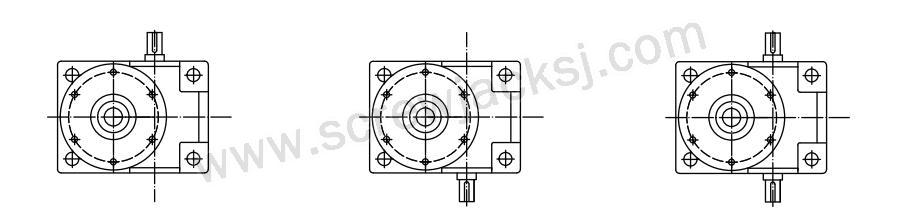

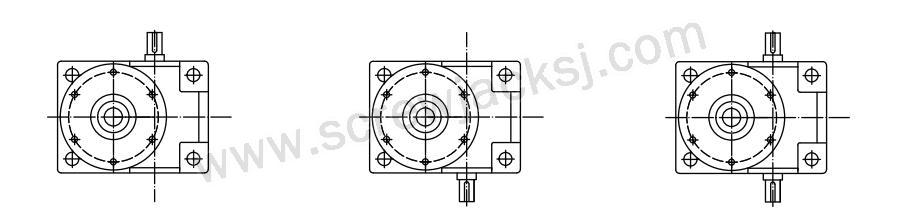

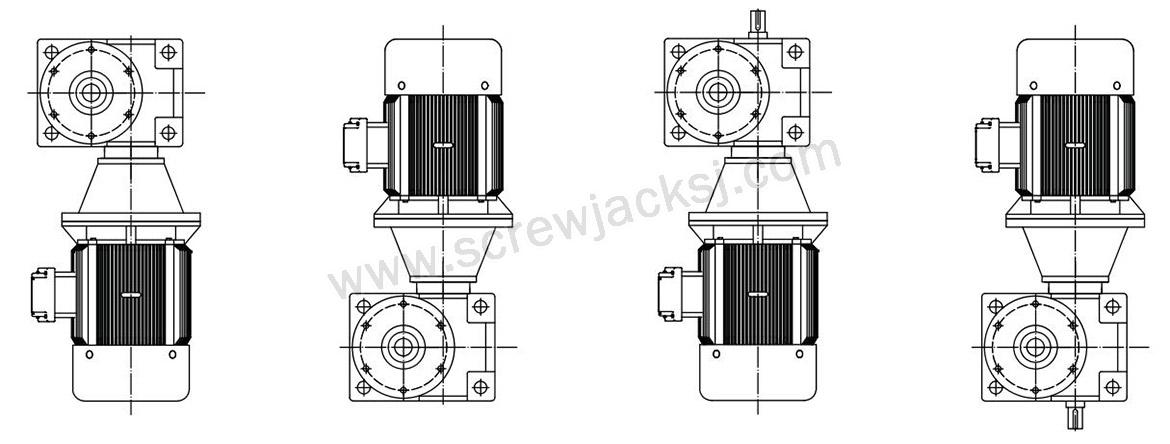

4: Worm Shaft Input Types

A: left side worm shaft input.

B: right side worm shaft input.

C: double worm shaft input.

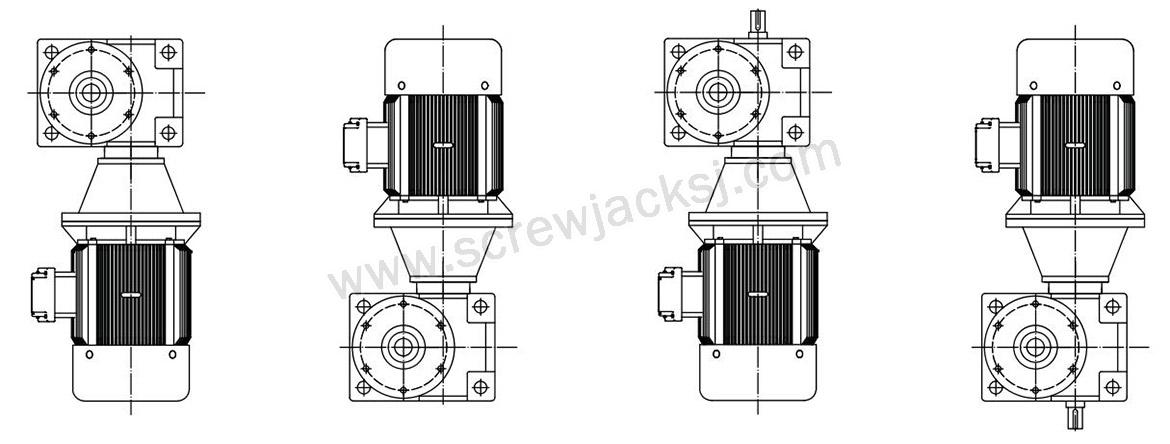

M1: left side motor flange direct input.

M2: right side motor flange direct input.

M3: left side motor flange direct input, right side worm shaft input.

M4: right side motor flange direct input, left side worm shaft input.

A B C

M1 M2 M3 M4

5: Gear Ratio:

SJD10: 1/4, 1/16. SJD11: 1/4, 1/16. SJD12: 1/4, 1/16. SJD20: 1/6, 1/24. SJD21: 1/6, 1/24 SJD22: 1/6, 1/24

SJD50: 1/7, 1/28. SJD51: 1/7, 1/28. SJD80: 1/8, 1/32 SJD81: 1/8, 1/32. SJD100: 1/8, 1/32 SJD101: 1/8, 1/32

6: Travel Stroke

No standard travel stroke, all the machine screw jacks’ travel strokes are processed according to customers' requirements.

7: Accessories

P: Protective Tube Standard

R: Dust Cover( Bellows boot)

Y: Hand Wheel

Other accessories,please check below picture

| Model | SJD10 | SJD11 | SJD12 | SJD20 | SJD21 | SJD22 | SJD50 | SJD51 | SJD80 | SJD81 | SJD100 | SJD101 | |

| Max. Lifting Load ( KN ) | 10 | 12 | 7 | 18 | 24 | 19 | 50 | 39 | 60 | 57 | 67 | 98 | |

| Screw Diameter and Lead ( mm ) | Ø20x5 | Ø20x10 | Ø20x20 | Ø32x5 | Ø32x10 | Ø32x20 | Ø40x10 | Ø40x20 | Ø50x10 | Ø50x20 | Ø63x10 | Ø63x20 | |

| Gear Ratio | H | 1/4 | 1/4 | 1/4 | 1/6 | 1/6 | 1/6 | 1/7 | 1/7 | 1/8 | 1/8 | 1/8 | 1/8 |

| L | 1/16 | 1/16 | 1/16 | 1/24 | 1/24 | 1/24 | 1/28 | 1/28 | 1/32 | 1/32 | 1/32 | 1/32 | |

| Travel length(mm) per full turn of worm Shaft | H | 1.25 | 2.50 | 5.00 | 0.83 | 1.67 | 3.34 | 1.43 | 2.86 | 1.25 | 2.50 | 1.25 | 2.5 |

| L | 0.31 | 0.62 | 1.24 | 0.21 | 0.42 | 0.84 | 0.36 | 0.72 | 0.31 | 0.62 | 0.31 | 0.62 | |

| Starting Efficiency % | H | 35 | 35 | 35 | 32 | 32 | 32 | 33 | 33 | 32 | 32 | 34 | 34 |

| L | 22 | 22 | 22 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 22 | 22 | |

| Working Efficiency % at 1500rpm | H | 59 | 59 | 59 | 58 | 58 | 58 | 59 | 59 | 58 | 58 | 58 | 58 |

| L | 42 | 42 | 42 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | |

| Max. Permissible power ( KW ) | H | 0.57 | 0.57 | 0.57 | 1.14 | 1.14 | 1.14 | 2.2 | 2.2 | 2.5 | 2.5 | 3.0 | 3.0 |

| L | 0.27 | 0.27 | 0.27 | 0.55 | 0.55 | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | |

| Starting torque at full load ( N.m ) | H | 5.6 | 13.4 | 15.6 | 7.4 | 18.9 | 31.5 | 35.5 | 51.4 | 37.3 | 70.9 | 41.7 | 136.8 |

| L | 2.2 | 5.3 | 6.2 | 2.9 | 7.9 | 12.6 | 14.2 | 22.2 | 14.9 | 28.4 | 16.7 | 54.7 | |

| No-load Torque ( N.m ) | H | 0.29 | 0.29 | 0.29 | 0.40 | 0.40 | 0.40 | 0.84 | 0.84 | 1.52 | 1.52 | 2.1 | 2.1 |

| L | 0.18 | 0.18 | 0.18 | 0.29 | 0.29 | 0.29 | 0.59 | 0.59 | 1.12 | 1.12 | 1.4 | 1.4 | |

| Jack Housing Materials | Nodular cast iron | ||||||||||||

| Weight without stroke ( kg ) | 6 | 6 | 6 | 9.5 | 9.5 | 10 | 23 | 24 | 38 | 40 | 62 | 64 | |

| Weight of screw ( kg ), per 100mm stroke | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 | 1.5 | 1.5 | 2.5 | 2.5 | 3.2 | 3.2 | |

| Remarks: 1: Efficiency is under grease lubrication 2: H: High speed gear ratio L: Low Speed Gear Ratio | |||||||||||||

Worm Gear Ball Screw Jacks Ordering Information Part Number:

SJD100 - US - T - C - 1/8 - 300 - P

1 2 3 4 5 6 7

1: Jack Model

SJD10, SJD11, SJD12, SJD20, SJD21, SJD22, SJD50, SJD51, SJD80, SJD81, SJD100, SJD101

Before selecting the jack model, please check above worm gear ball screw jacks specifications.

2: Screw Configuration & Mounting Orientation

US: Upright translating screw UK: Upright keyed screw UR: Upright rotating screw

IS: Inverted translating screw IK: Inverted keyed screw IR: Inverted rotating screw

Note:US,IS (Screw rotation, do axial motion) UK, IK (Screw anti-rotation, do axial motion) UR,IR(Screw fixed rotation, traveling nut do axial motion)

US IS UK IK UR IR

3: Screw End Conditions

|

|

|

|

|

|

| T: Top Plate | H: Clevis End | R: Plain End | S: Thread End | U: Forked Head | SH:Spherical Hinge |

4: Worm Shaft Input Types

A: left side worm shaft input.

B: right side worm shaft input.

C: double worm shaft input.

M1: left side motor flange direct input.

M2: right side motor flange direct input.

M3: left side motor flange direct input, right side worm shaft input.

M4: right side motor flange direct input, left side worm shaft input.

A B C

M1 M2 M3 M4

5: Gear Ratio:

SJD10: 1/4, 1/16. SJD11: 1/4, 1/16. SJD12: 1/4, 1/16. SJD20: 1/6, 1/24. SJD21: 1/6, 1/24 SJD22: 1/6, 1/24

SJD50: 1/7, 1/28. SJD51: 1/7, 1/28. SJD80: 1/8, 1/32 SJD81: 1/8, 1/32. SJD100: 1/8, 1/32 SJD101: 1/8, 1/32

6: Travel Stroke

No standard travel stroke, all the machine screw jacks’ travel strokes are processed according to customers' requirements.

7: Accessories

P: Protective Tube Standard

R: Dust Cover( Bellows boot)

Y: Hand Wheel

Other accessories,please check below picture