This case uses two SJD-20 cubic ball screw jack systems. After the motor is decelerated by the reducer, the power is transmitted through the connecting rod and the coupling to realize the two synchronous lifting functions. The lift has its limit switch, which can control the workplace to stop automatically at the limit position. Compared to conventional screw jack, ball screw jack allow for a higher frequency of use and lift speed for longer life.

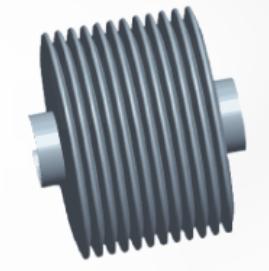

Ball Screw Jack Ball Screw Jack |

Worm Gear Reducer Worm Gear Reducer |

Couplings Couplings |

Connecting Shaft Connecting Shaft |

This case is a typical lift four screw jack system, and the layout is H-shaped. Since the center height of each component is different, the mounting surface and the mounting hole are processed after the mounting plate is welded at different height positions on the square pipe frame. After assembly, the axes of the components are in the same horizontal position. The screw rod is made of ball screw and controlled by a servo motor. The synchronization accuracy can reach within 0.05mm.

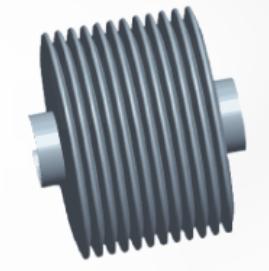

Ball Screw Jack Ball Screw Jack |

Bevel Gearbox Bevel Gearbox |

Servo Motor Servo Motor |

Couplings Couplings |

Connecting Shaft Connecting Shaft |

In the case, to facilitate the installation, the articulated shaft is hinged to the support frame of the radar on the body of the worm gear screw jack, and the head of the screw rod is a flat head, which is hinged to the receiver of the radar through the pin shaft. The geared motor is directly connected with the worm of the worm gear screw jack to drive the worm to rotate, thereby controlling the vertical rotation of the radar receiver. The inside of the rotating frame controls the rotation of the receiver in the horizontal direction through the slewing support. The two functions are combined to make the radar fully azimuth ability to detect targets.

Screw Jack Screw Jack |

Geared Motor Geared Motor |

Bellows Bellows |

Couplings Couplings |

In this case, the ball screw bevel gear lifter is linked in five units, which has faster lifting speed and higher transmission efficiency than the worm gear worm lift. However, the mechanism cannot be self-locking and requires the use of a brake or a motor with a brake. When the lifting speed is high, it is recommended to use the variable frequency motor to run the motor at a slower speed during starting and stopping, which can reduce the impact on the equipment and make the equipment run smoothly.

Bevel Gear Jack Bevel Gear Jack |

Brake Motor Brake Motor |

Bevel Gearbox Bevel Gearbox |

Couplings Couplings |

Connecting Shaft Connecting Shaft |

The switch plays an important role in the railway line, which is a line connecting device that turns a rolling stock from one lane to another. When laying the ballast, it is necessary to fine-tune the height of the rails to ensure that the adjacent rails are at the same level. When in use, the rails are connected indirectly to the cabinet of the elevator through the connecting plates. The head of the elevator is flanged downwards and supported by the ground. The driving source can realize the lifting and lowering of the box by rotating the worm through the pulley, thereby realizing fine adjustment of the rail in the vertical direction. When the elevator is equipped with a pulley, the ratio of the driven wheel to the driving wheel is larger under the same load condition, and the larger the speed ratio of the elevator, the smaller the driving source power.

Machine Screw Jack Machine Screw Jack |

Hand Wheel Hand Wheel |

The screw jack is connected through the hinge hole of the trunnion plate and the base of the photovoltaic support, and the photovoltaic support and the base are also connected by an articulation. The reduction motor is directly connected by the transfer flange and the elevator to control the lifting and lowering of the screw rod, thereby adjusting the clamp of the solar photovoltaic panel and the horizontal plane angle. In this case, the device is used in an outdoor environment, so the telescopic dust cover is added to prevent the screw from rusting.

Screw Jack Screw Jack |

Bellows Bellows |

Motor Motor |

Mounting Base Mounting Base |

The input shafts of the two jacks are connected by a connecting rod, and the geared motor drives the connecting rod to rotate through the sprocket, thereby driving the nut to lift and lower. The chuck for clamping the welded piece is connected to the nut through the bottom plate, and the chuck is driven to rotate by the gear. In this way, the lifting and rotating of the welding piece is realized, which facilitates the welding of the robot. The elevator screw is equipped with a steel sheath. It can effectively prevent welding slag, dust and the like from entering the inside of the screw.

Machine Screw Jack Machine Screw Jack |

Motor Motor |

Gear Chain Gear Chain |

Couplings Couplings |

Connecting Shaft Connecting Shaft |

Due to the large size of the fryer, generally, the four sets screw jack actuator is used in the frying machine and is driven by a motor. According to the actual working conditions, the reducer can be selected to meet different lifting speed requirements. When the frying machine is working, the raw materials are first transported to the storage tank through the conveying mechanism, and the heating system works. After the oil temperature reaches the specified requirements, the jack actuator pushes the storage tank down, and the raw materials enter the oil. Bring the raw materials into full contact with hot oil. After frying for a certain period, the screw jack actuator drives the storage bin up and separate the fried food from the oil. Finally, the fried food is transported to the next process by the transport mechanism

Screw jack actuator Screw jack actuator |

Motor Motor |

Pillow Block Pillow Block |

Couplings Couplings |

Connecting Shaft Connecting Shaft |